CAPABILITIES

Dynamic Weld Specializes in the design and manufacturing of material handling racks and containers.

LEARN MOREAbout Us

A combined forty-five years of metal fabrication experience.

Founders Harry Heitkamp and Gene Niekamp incorporated Dynamic Weld in 1981. Their Combined forty-five years of welding experience laid a foundation for Dynamic Weld Corporation’s consistent and steady growth. Their business started in a 1200 square foot building where most of their work was provided by area farmers and local manufacturing companies.

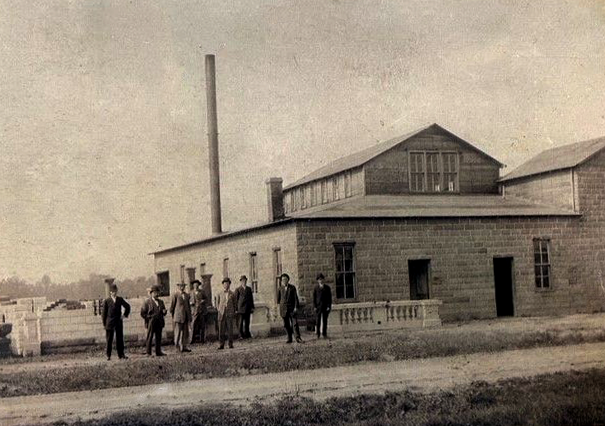

The original Osgood cement tile factory.

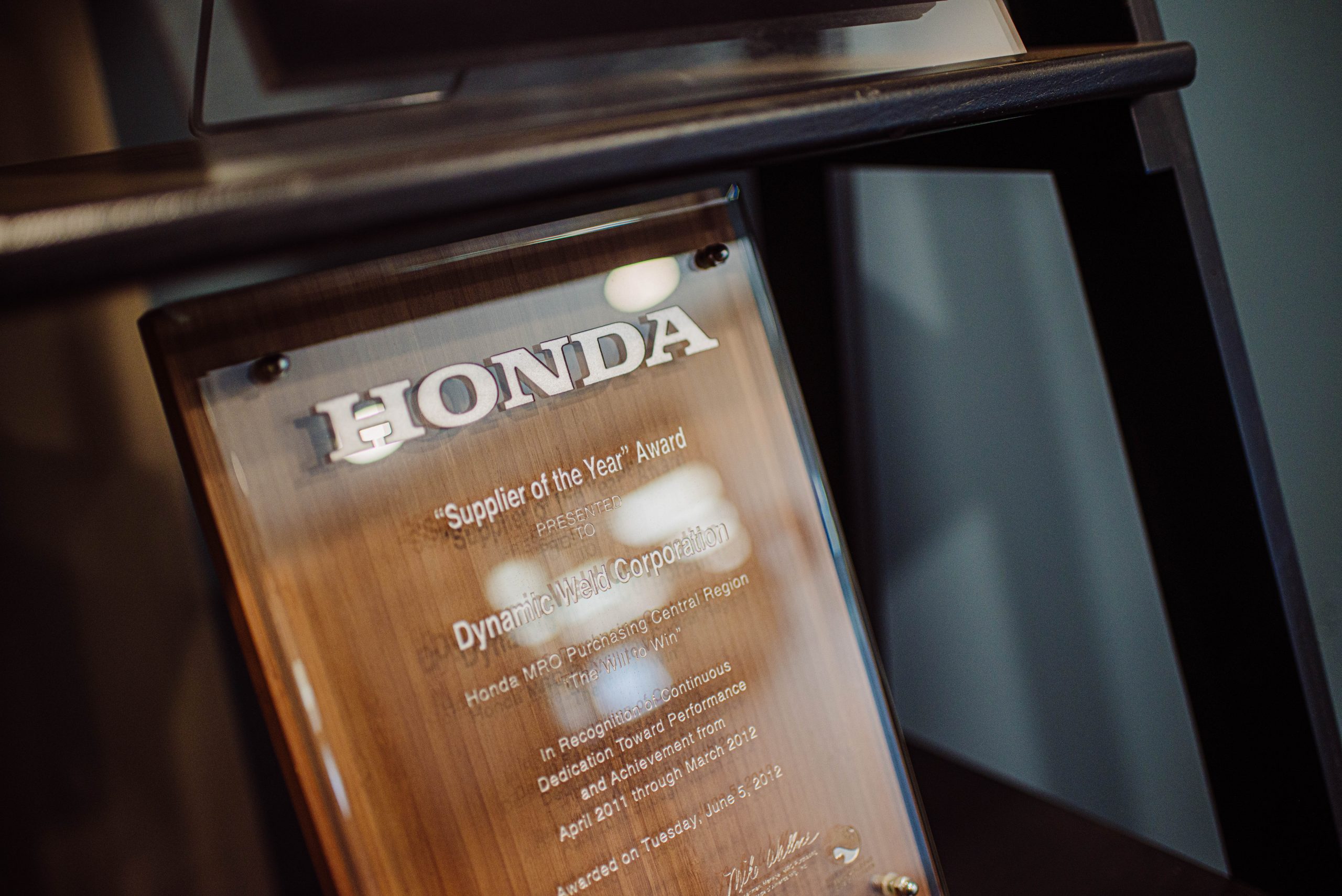

Dynamic Weld grew to become a key supplier to global companies such as General Motors, Chrysler, Honda of America, and International Truck. In 1986, the Osgood cement tile factory was purchased and converted to a large weld shop. Dynamic Weld quickly found a niche in the metal fabrication industry when Honda of America built its first facility in nearby Anna, Ohio. Dynamic Weld began creating prototypes and mass-producing custom material handling and returnable shipping containers for each of Honda’s plants. Dynamic Weld continued its growth by adding global companies, as well as many large tier 1 automotive suppliers.

In 1991, a 20,000 square foot building was constructed on-site to house the prefabrication and welding departments and the original tile plant building was converted to a paint and assembly area. This addition enabled the company to complete larger projects and shorten delivery lead times.

In 1997, the original tile plant building was demolished and a 20,000 square foot building was constructed in its place, complete with two enclosed loading docks and an electrostatic paint system.

In 2020, a local machine shop was purchased and its equipment and employees were moved into a new building addition.

In 2022, an 8 KW Cincinnati Machine Fiber Optic Laser machine was installed, capable of laser cutting one-inch thick plates.

Growth and expansion has been a consistent pattern for Dynamic Weld. Currently, we have 60,000 square feet, two shipping docks and 3 acres of open lot space for rack storage.

OUR Capabilities

Dynamic Weld is ISO 9001:2015 Certified

Machined Parts and Fabrication of Custom Racks, for Shipping and Storage of Parts, for Various Industries

We have manufactured automotive material handling racks which include:

• INSTRUMENT PANEL

• ENGINE COMPONENT

• EXHAUST SYSTEM

• BRAKE SYSTEM

• HEAD LINER

• ENGINE

• TRANSMISSION

• WHEEL

• SEAT

• INTERIOR TRIM

• EXTERIOR TRIM

• FUEL TANK

• BRAKE LINE

• STEERING WHEEL

• GLASS

• DOOR FRAME

• PILLAR

• CENTER CONSOLE

• GLOVE COMPARTMENT

• SPOILER

• SUNROOF

• GEAR BOX

• AUTOMOTIVE STAMPINGS

(BASKETS)

OUR WORK

SUPERIOR QUALITY … MINIMAL COST.

We believe engineering excellence is the key to cost effective shipping containers. We use 3D part model data to develop custom containers, eliminating the need for multiple prototypes and reviews.

We are able to save our customer’s time and money through virtual rack reviews.

DESIGN

Learn More

MACHINING

Learn More

MASS PRODUCTION

Learn More

FIBER LASER CUTTING

Learn More

PROTOTYPES

Learn More

PAINT

Learn More

OTHER FABRICATION

Learn More

TRUCKING

Learn MoreOUR EQUIPMENT

DYNAMIC WELD CAN HANDLE YOUR LARGE PROJECTS WHILE STILL GIVING YOU THE INDIVIDUAL HELP AND ATTENTION THAT YOUR SMALLER PROJECTS DESERVE.

NO PROJECT IS TOO BIG OR TOO SMALL.

Fabricating Equipment

• 2022 Cincinnati CL 900 fiber laser cell – capable of cutting up to 1″ mild steel 60 x 120″

Amada bundle Saws

• 16” x 16” capacity

CINCINNATI 300 TON PRESS BRAKE

• ½” x 12’ capacity

Cincinnati 90 Ton Press Brake

10′ Bed

• 3/16″ x 8′ capacity

Accushear (2020)

• 1/4″ x 10′ capacity

boschert notcher

(2) tig welders

11 gauge x 6′ roll

(2) motoman 1800 robotic welders

MATERIAL HANDLING DELIVERY EQUIPMENT

• (3) 5 Ton Overhead Cranes

• 1 Ton Jib Cranes

• (7) 5,000 Lb. Fork Lifts

15,000 Lb. Fork Lift

10,000 Lb. Fork Lift

(3) VERTICAL MILLING machining centers

Fryer VB-60

Fryer MC-60

Fryer MB-10R

Paint Equipment

• 20 ft. x 50 ft. Hot Phosphate Steam Booth

• 20 ft. x 12 ft. Paint Booth

• (2) Electrostatic Paint Systems (Water Based Liquid Paint)

approved vendors

Stellantis

International

Kenworth

Volkswagen

Rivian

GM

Subaru

Honda

GET A QUOTE

The individual help and attention you deserve.